“If you wanted to make a difference, there was an opportunity. “

Our passion for ribbon microphones runs deep. It’s woven into every ribbon and every microphone we craft. But the mics’ ability to capture sound with unparalleled warmth and nuance wouldn’t be possible without the skilled hands of our team.

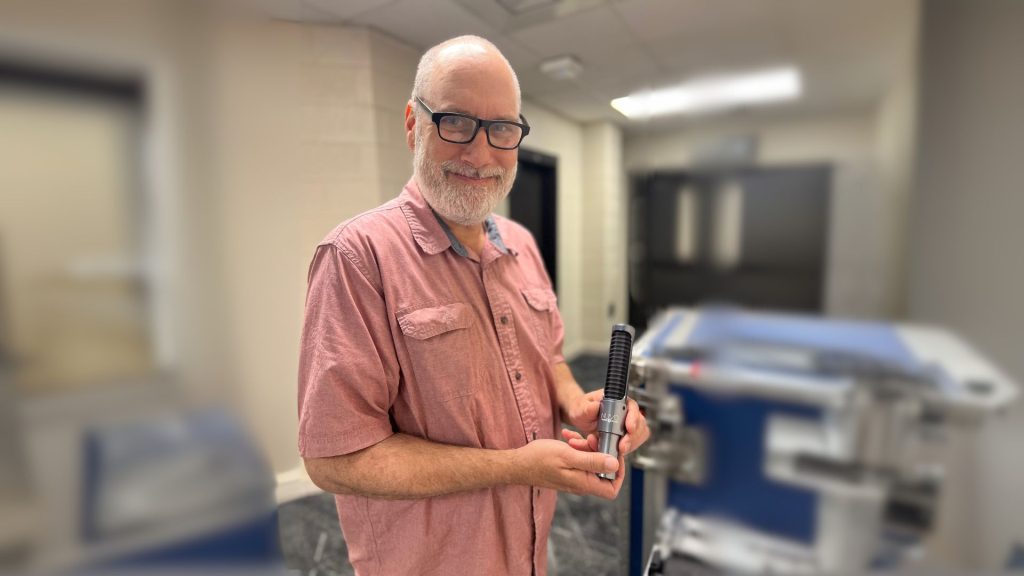

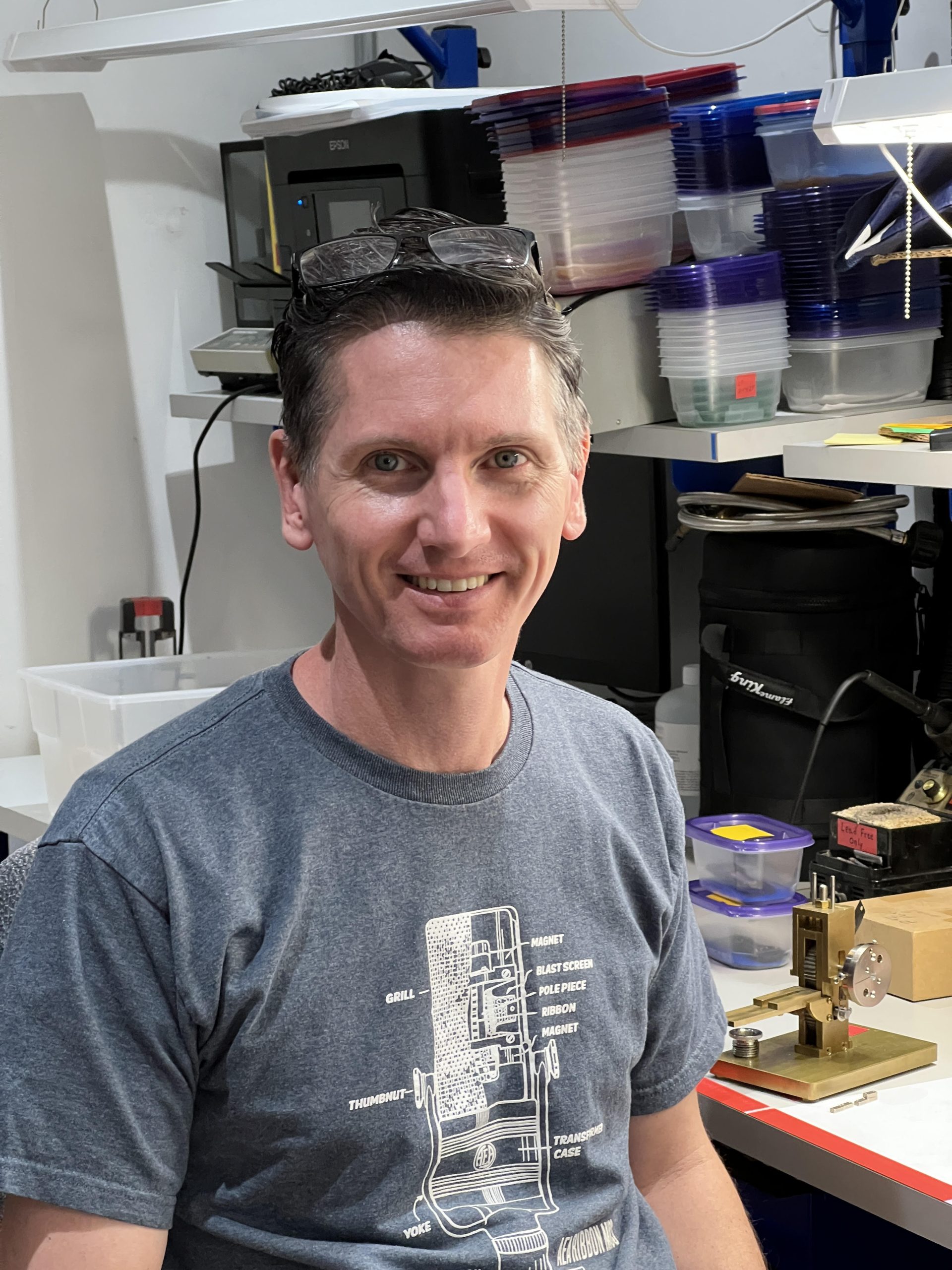

Today, we spotlight Jeremy Hopkinson, our expert ribboner, whose precision and dedication play a vital role in our mics’ quality and consistency. He helps ensure each one delivers the sonic magic that defines our legacy. Join us as we talk to Jeremy about his journey at AEA, explore the intricacies of ribbon microphone construction, and why he still calls AEA home after two decades.

How did you get your start at AEA?

I actually came into AEA doing office work, honestly. Wes (Dooley, Founder of AEA) was looking for somebody detail-oriented to bring organization to the office. I was the one who first started making our advertisements, and I was the first one who developed our website. I was also the first one that started doing purchasing, once we started making microphones. That was in about 2000. I’ve been here ever since.

At the time, someone else named Rebecca was doing the ribboning. She was the one who taught me how to cut ribbons. I’m still using her method. I was excited to do it because it was something that was more hands-on. It was a smaller shop back then. If you wanted to make a difference, there was an opportunity.

Talk about the ribbon materials you work with.

We used to use the same material as the original RCA ribbons. As a matter of fact, when we first got started, it was new old stock RCA material from the ’60s. Now, it’s a flat sheet of aluminum leaf. We put the aluminum leaf through a specially made crimper, which is a set of gears that are customized for us.

The ribbon material goes in between those gears, and they introduce a sinusoidal shape crimp into it. That crimp helps it absorb a lot more motion of the air and a lot more wind. If you put a flat ribbon in a motor and then put it in front of a kick drum, you would blow it out in a second.

So I cut [and crimp] the ribbons and put them in the motors. Motors, basically, are the structure that holds the magnets where they belong and where you put the ribbon.

Do you also tune the ribbons for each mic?

Yes. I use the old RCA way. I tap on it, and that pushes air against it and stresses it out. Through that process, the ribbon tension falls to a place where it naturally stops. There’s a target frequency that I shoot for.

There’s definitely a little bit of finesse to it. You have to develop an eye to see that it’s centered and straight. It’s something that requires a disposition toward precision.

Being a professional ribboner is a particular job. How many others are there in the U.S.A.?

I think only a few companies do ribbon mics like us. I think most of the companies that make ribbon mics make condensers as well as ribbons and might get things from overseas. So there aren’t many ribboners in the U.S..

But, man, I would feel very sketch about getting a ribbon made by anybody outside, even if it was somebody domestically. I mean, you would spend as much time QC’ing as you would spend doing the work yourself. It’s such a specific thing.

Do you have a background in recording? If so, what are your favorite AEA ribbon mics?

I have a bit of background in recording and have used both condensers and ribbons. I feel like ribbon mics are very good for the voice and especially for strings. I think the N8 is my favorite. I like the KU4 (with supercardioid polar pattern) as well because I don’t have as many challenges in post trying to figure out how much cancellation is going on.

What ribbon mic myths would you like to bust?

I think, 20 or 30 years ago, people were afraid to touch a ribbon mic because they thought it was just too fragile. They thought, “I can’t even touch it.” But they’re not if you treat them right. Even if you blow out a ribbon, the integrity of everything else is rock solid.

You’ve been with AEA for over 20 years. What has kept you there so long?

I have everything I need here, and it’s also a lot more professional internally. Julie Tan (Owner of AEA), is taking the company to the next level where we’re competitive with bigger players in the audio industry and developing more brand awareness. That can only be good for the stability and long-term growth of the company. Her leadership is important.

The Human Touch Behind AEA Microphones

Jeremy’s journey exemplifies the heart and soul of AEA. His dedication to precision, his deep understanding of ribbon technology, and his passion for capturing sound in its purest form are all reflections of the values we hold dear.

We keep the entire AEA family extremely close and believe that human touch is essential to crafting our microphones. Jeremy and our entire team are the key to ensuring every AEA ribbon microphone remains a showcase of legacy, craftsmanship, and innovation.